Recognizing the Capability of Membrane Layer Changes for Interface Tools

The performance of membrane switches over represents a significant advancement in user interface style, incorporating efficiency with visual convenience. As industries increasingly prioritize individual experience, understanding the subtleties of membrane switch innovation becomes important.

What Are Membrane Layer Switches?

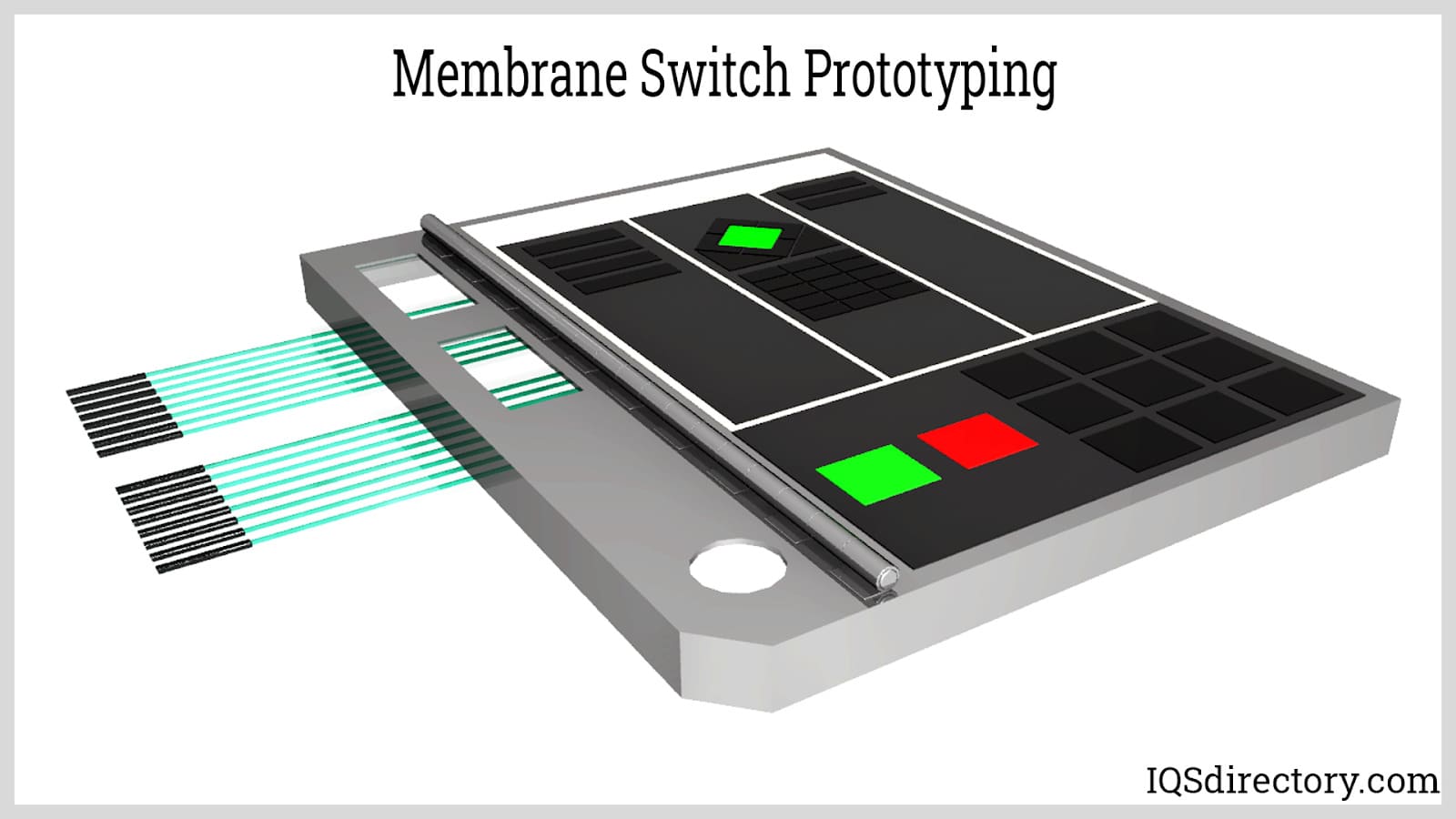

Membrane buttons are cutting-edge user interface devices that facilitate customer communication with electronic tools. These flexible elements include numerous layers, consisting of a graphic overlay, spacer, and a printed circuit layer. The design enables for a seamless combination right into various electronic gadgets, enhancing both the aesthetic and practical elements of interface.

Membrane buttons are frequently utilized in a wide variety of applications, from household devices to commercial machinery and clinical devices. Their building and construction typically features a thin profile, making them an optimal selection for small layouts. The responsive comments offered by these switches can be crafted to satisfy specific customer choices, guaranteeing reliable communication in between the individual and the gadget.

Longevity is one more significant benefit of membrane layer buttons, as they are resistant to dust, moisture, and chemicals, which boosts their lifespan in demanding settings. Furthermore, these switches can be personalized in regards to shape, size, and graphic layout, enabling branding and user-specific functions. Generally, membrane switches over represent a useful solution for boosting user experience in digital tools, incorporating functionality with visual charm in a reliable manner.

Just How Membrane Layer Changes Work

Operating on a simple concept, membrane switches over use a split construction to sign up user input effectively. Each switch contains multiple layers, including a printed circuit layer, a spacer layer, and a top visuals layer, which are developed to interact flawlessly. When a customer presses the top layer, it presses the spacer layer, bringing the conductive aspects of the circuit layer into contact with each other.

This call creates a closed circuit, signaling the device to implement a certain feature. The layout enables various configurations, consisting of responsive responses, which can boost the user experience by providing a physical feeling upon activation. The materials utilized in membrane buttons frequently include flexible substrates, such as polyester or polycarbonate, which make certain longevity and durability against wear and tear.

Key Advantages of Membrane Buttons

One more significant advantage is their compactness. Membrane layer switches are slim and light-weight, which allows makers to save area in their devices without giving up performance. This function is particularly helpful in applications where weight and quantity are important considerations.

In addition, membrane layer buttons are resistant to dirt, moisture, and chemicals, improving their resilience. This strength extends their life-span and minimizes the demand for frequent replacements, leading to price savings with time.

Additionally, the responsive comments given by membrane layer switches can be optimized to boost user communication. They can include functions such as increased buttons or distinct clicks, enhancing functionality and user experience.

Applications Throughout Industries

Individual interface devices utilizing membrane switches are widespread in a broad array of sectors, showcasing their versatility and capability. Membrane Switch. In the medical industry, membrane buttons are important to gadgets such as diagnostic tools and patient tracking systems, where their toughness and convenience of cleansing are important for preserving health requirements. In the auto market, these buttons are used in dashboard controls and infomercial systems, providing a smooth and modern user interface for individuals.

Additionally, the customer electronics industry advantages from membrane switches in home appliances and handheld tools, where small design and user-friendly interfaces enhance user experience. Industrial applications likewise leverage membrane switches over for control board in machinery and automation systems, stressing their effectiveness and resistance to severe environments.

In the aerospace and defense industries, membrane layer buttons are utilized in cabin controls and equipment, where reliability and performance under extreme problems are extremely important. Furthermore, the pc gaming industry increasingly integrates membrane layer buttons in controllers and gallery equipments, adding to an interesting user experience. Generally, the convenience of membrane switches enables their widespread usage across numerous markets, emphasizing their significance in modern interface style.

Future Fads in Membrane Layer Switch Over Modern Technology

Furthermore, making use of sophisticated materials, such as polycarbonate and polyester movies, is expected to rise, offering improved resilience and resistance to environmental stressors. These materials contribute to the total longevity of membrane buttons, making them you can try these out suitable for harsher commercial applications.

Moreover, the incorporation of wise modern technology, including IoT connectivity, will certainly allow membrane buttons to communicate with other devices and systems, facilitating a more interactive customer experience. This trend lines up with the expanding need for smart gadgets throughout numerous markets, from healthcare to customer electronic devices.

Lastly, modification options are expected to increase, enabling producers to create bespoke options customized to particular individual requirements and choices. These advancements will certainly place membrane layer switches as important components in the advancement of user interface modern technology.

Verdict

In final thought, membrane layer changes stand for a crucial development in customer interface technology, providing a trustworthy and flexible solution for diverse electronic applications. As improvements in material scientific research and touch noticing modern technologies proceed, the functionality and applicability of membrane see this page buttons are expected to broaden, enhancing their value in modern-day electronic gadgets.